FREQUENTLY ASKED QUESTIONS : GENERAL QUESTIONS

FAQ – LSLXRX STANDARD HEADSAIL FURLERS

How to dismantle one Facnor LS/RX manual furling system?

For this type of operation, we recommend to enter in contact with one of our distributors or agents. Access to our distributor/dealer list

Please also refer to our installation manuals by clicking on the following link : Headsail furlers technical informations

.

My furling line is overlapping, what to do?

In order to prevent from overlapping keep the furling line tight, also check that the furling line is properly fitted according to our instructions page 13 paragraph 5 : LS/LX/RX installation Manual In any case, we recommend to contact one of our distributors or dealers.

How to fit the the furling line of my Facnor furling gear?

Please follow instructions page 13 paragraph 5 of the LS/LX/RX furling systems : LS/LX/RX Installation manual

In any case, we recommend contacting one of our distributors or dealers : Access to our distributor / dealer list

The halyard gets wrapped round the forestay, what shall I do?

Stop immediately furling the sail in order to avoid any damage. Two possible reasons:

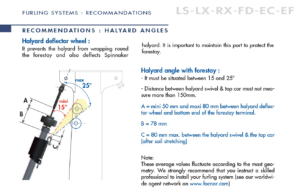

– the angle formed by the halyard and the forestay is to closed. The geometry pf the top fitting of your furling systems needs to be reviewed in order to open this angle. Please refer to page 14 paragraph 8 « Specific installations » of the LS/LX/RX installation manual.

– the rotation of the top swivel is stiff, bearings needs to be checked.

In any case, we recommend to contact one of our distributors or agents. Access to our distributor/dealer list

Access to our distributor/dealer list

Before using your Facnor furling and reefing system we recommend to carefully read our use instructions of our installation manual:

– Always keep the Genoa halyard tight when furling in and out;

– Do not tight excessively the halyard; stop tightening as soon as the folds in the sail have disappeared;

– If necessary change car position according to the sheet angle, thus the loads will better distributed along the luff;

– When reefing in light airs, maintain some tension on the jib sheets to ensure the sail is properly rolled up;

– Slack the halyard at the harbour;

– DO NOT FORCE the reefing system. Check for reasons if the sail is difficult to furl. Above all DO NOT USE the winch to furl in. Please contact your Facnor distributor/dealer ;

– Before leaving your boat, make sure that the sail is tightly furled and that the jib sheets are wrapped around the furled sail two or three times, and the reefing line is secured;

– In case of difficult rotation, check that no halyard (Spinnaker halyard for instance) is interfering;

– Regarding maintenance, please see page 21 INSTRUCTION MANUAL

Where can I find the installation for my Facnor manual furling and reefing system?

Click on the following link : Facnor installation manual

How to service my Facnor furling and reefing system?

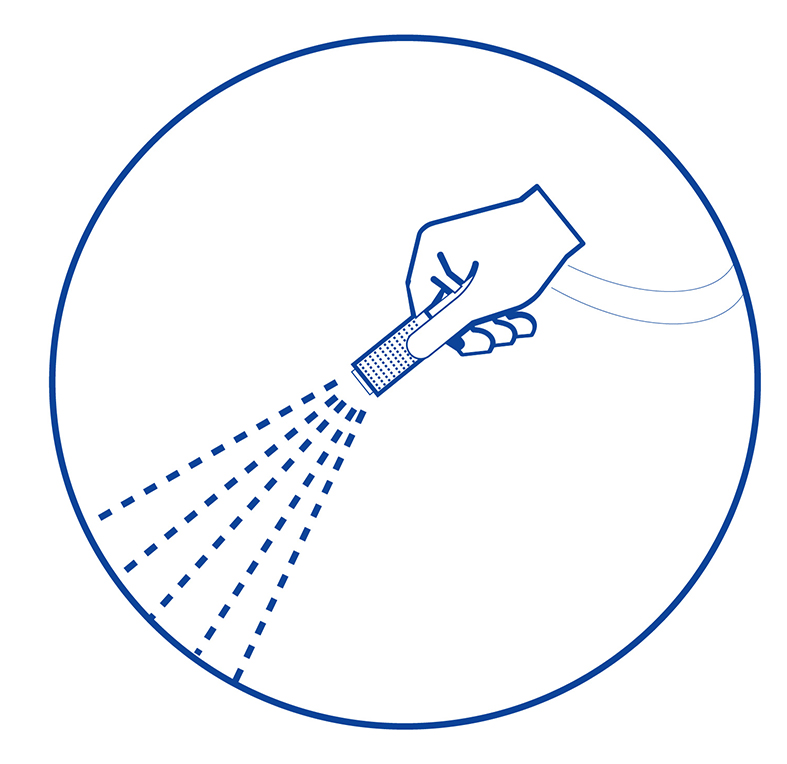

Facnor furling equipment requires no maintenance, however it is highly recommended to rinse your furling systems with clear water several times during the season. Salty deposits having a corrosive effect, it is needed to prevent from salt accumulation.

Facnor furling equipment requires no maintenance, however it is highly recommended to rinse your furling systems with clear water several times during the season. Salty deposits having a corrosive effect, it is needed to prevent from salt accumulation.

What are LS/RX kit components?

The LS/RX standard kit includes:

- Two sealed mechanisms: drum + halyard swivel,

- A set of anodized foil sections, connectors, nylon bushings, one telescopic section, one sail entry, one top cap, one halyard deflector wheel, screws.

What is the difference between the cruising and the racing range?

The cruising range gathers LS and LX models, equipped with round anodized foil section with twin groove. The racing range corresponds to the RX models equipped with elliptical, aerodynamic and light twin groove foil sections.

What are the discrepancies between the LS and RX furlers?

The LS furlers are fitted with standard non removable drum whereas the LX drum plates (former range) can be removed and the tack fitting can rotate. LS and LX furling gears are delivered with round foil sections.

Concerning the RX furlers, they are delivered with elliptical, aerodynamic and light foil sections. The plates are removable for use as head foil and the tack fitting is rotating.

How to choose the right Facnor manual furling and reefing system for the headsail of my boat?

The choice of the Facnor furler model for my headsail depends on the size of my boat, the diameter of the forestay and the area of the Genoa. In order to validate your choice, please do not hesitate to contact one of our distributors or dealers. Access to our distributor/dealer list

FAQ – QUESTIONS ABOUT FD WEBBING HEADSAIL FURLERS :

Can I install a Flat Deck furler on my boat?

To ensure that assembly is possible, you need to count the number of turns necessary to roll in your headsail and measure the distance between your drum and your cleat. You can then refer to the chart of the FD installation manual to check if you can install the Flat Deck. See page 28 of the Installation Manual

If the distance between your drum and your cleat is too short (or the number of turns too large) you can lengthen the way through the furling line runs.

Can I keep the fairleads that I already have on my boat?

The Facnor fairlead set is in the Flat Deck standard kit. Indeed, the webbing fitted with swivel used on the Flat Deck may not properly slide through some fairleads (especially those with sheave). But we thought of everything.

What does the FD standard kit includes?

The FD standard kit includes :

> the drum fitted with 360° orientating line guide, low profile foot and rotating tack fitting

> the halyard swivel (modif version FR enlever haute résistance)

> the internal turnbuckle fitting

> the short link plates in stainless steel (longer link plates available as option)

> the foil sections (elliptic or round) and connectors

> the high load webbing kit assembled to a rope with swivel

> the fixed stanchion fairleads (numbers depending on FD model) and one articulated fairlead to be fitted next to the drum.

Is it possible to change the webbing of the FD drum?

Yes the furling webbing can be changed. It’s a removable element.

Is the strap strong enough?

The FD range has been launched by Facnor for more than a decade. So we got feedback from its use and have been improving FD in details over the years.

We use high-performance, high-load and low-stretching webbing (polyester for FD90 to 190 and Dyneema for FD210 to 310)

We recommend preserving the webbing thanks to the more appropriate deck configuration, regular rinse and good use (see FD Installation manual)

What are the differences between the FD-R racing range and the FD-SX comfort range?

The FD-R racing range benefits from elliptical foil sections (R14/24/26/34).

The FD-SX comfort range is fitted with rounded foil sections (SX 25/33/39/47/53).

FAQ – QUESTIONS ABOUT EC/EF+ ELECTRIC HEADSAIL FURLERS

What are the differences between the EF+ and EC ranges?

My Facnor electric furling systems is losing power, what can I do?

First of all distinguish whether the failure is mechanical (due a not released sheet released, halyard interfering with the swivel, …) or electric (due to battery discharged, short circuit,…). On board, proceed by eliminating the possible reasons and preventing from eventual emergencies.

Back at the harbor contact your agent to carry out a complete check-up of the installation.

What type of engine is used with the electric furling system?

The range of EC electric furlers are equipped with an innovative multi-engine concept.

EC39 multi-engine drive unit (12V), 400W power, 40 rpm, optimal torque 45 Nm and maximum 115 Nm

EC47 multi-engine drive unit (12/24V), 800W power, 55 rpm, optimal torque 55 Nm and maximum 135 Nm

Is it easy to power my Facnor manual furling gear?

Yes, motorizing its Facnor manual furling system simply requires the drum to be changed by an electric drive unit, the existing foil sections and halyard swivel cursor remain. All you need is a motorization kit that includes the electric drive unit, the relay box and the circuit breaker. To validate the choice of the motorization kit, do not hesitate to contact one of our dealers.

How do I choose the right electric furling and reefing gear for my boat?

The choice of electric furler is based on the size of your boat, the diameter of the forestay and the surface of your Genoa. To validate your choice, please contact one of our dealers.

Why prefer a radio command to a wired command?

The radio control allows greater freedom of movement (front/rear and Port/Starboard) on the boat, especially on long sailboats.

FAQ – QUESTIONS ABOUT HF HYDRAULIC FURLERS

From what size of boat can a hydraulic furler be fitted?

The HF range starts from 42 ″ up to 75 or 80 ′.

I don’t have a hydraulic unit, is it possible to fit a hydraulic furling gear?

Yes, it is as Facnor offers optional hydraulic power kits for supplying the hydraulic furlers.

Is it possible to switch from a manual furling system to an hydraulic one?

Yes, it is. Facnor has developed models compatible with the size of standard drums as well as with original Facnor foil sections (SX47 & SX53). And they can also be mounted with carbon profiles for more lightness.

What is the advantage of a hydraulic system?

- More and more long sailboats are equipped with hydraulic power stations.

- These systems preserve on-board electricity and are fitted with strong et reliable connections.

- Constant torque, powerful and quiet

- Hydraulic furling systems are known for their good durability

Contact the Facnor dealers network

STG / STB / FLT / STK STRUCTURAL HEADSAIL FURLERS

What are the differences between a structural furler and Code sail furler?

The structural furler supports the mast and also furls the sail – whereas a Code sail furler enables only to roll in and out the flying sail. In case of structural furler, the forestay wire between mechanisms is made of stainless steel or textile according to sailboat length.

Why use a structural furler rather than a standard furling system?

The only reason is: performance.

As weight in highs is the enemy of performance, the structural furler offers the possibility of drastically reducing it.

For example, on a 35 ’boat, a structural furler weighs 3.5 kg compared to 25 kg for a furling gear …

What charge for a structural furler?

The load of a structural furler is defined by the stainless steel wire that the furler will replace (the boat sizes given are only indicative).

Structural furler: endless line or classic drum?

The endless line is more compact than a drum (to optimize the luff length) and has the advantage of having a larger maneuvering Ø to provide less torque effort (prevent from line overlapping). However, you need a deck plan suitable for the passage of continuous rope.

To prevent the sail from rolling out, you will need to make sure that you have tensioned the furling line.

A classic drum simplifies the deck plan, and above all secures the sail better in the furled position (only one cleat to operate). However, make sure that the storage capacity of the drum is sufficient to be able to completely furl your sail.

Can I partially furl my headsail when it is fitted on a structural furler?

No, you cannot. The structural furlers are used as in/out furler. Partial furling is not possible.

Can I hoist and lower my sail easily?

For structural furlers fitted with wire equivalent to 1 × 19 of 7 mm and less :

- We offer simple hoisting and lowering solutions.

- The STB has a sheave integrated into the swivel to lower the halyard along the luff.

- The STG comes standard with a halyard swivel to be able to hoist, adjust and lower the sail from the cockpit.

- For the FLT, the halyard swivel is optional.

For wires equivalent to 1 × 19 of 8 mm and more :

- We recommend the use of a textile wire with a sail with zipped luff.

- Installation: it is necessary to climb the mast to hoist and fix the sail. For lowering the sail, same opertaion but there are cost-effective solutions, please contact us.

- Locks: It is also possible to lock your genoa in order to hoist it and simply lower it from the deck: please contact us for presenting “custom” solution.

Is it possible to vary the forestay length to adjust the shape of my mast?

Structural furlers with wires equivalent to 1 × 19 of 7 mm and less are delivered with adjusting link plates allowing the length of the forestay to be adjusted.

For larger sizes, this adjustment is generally made through a textile attachment assembled onto the bottom and / or top mechanism.

What do the names of the structural furler correspond to?

The trade names (STK 5T, STK9T,…) correspond to the working load of the equivalent Rod cable (refer to the chart).

Up to what size of stainless steel wired forestay can a structural furler be used?

Facnor structural furlers can be used for forestay up to 7 mm diameter.

Beyond, it is necessary to go for a structural furler fitted on textile forestay.

What are the different possible configurations for a structural furler?

A structural furler can be configured in different ways: with various upper and lower end fitting. Many endings are possible (swivel eye at the bottom, twin spool or lashing eye at the top ..). In addition, the endings are switchable as they are screwed to the mechanisms.

See Facnor endings

Contact the Facnor dealers network